Iron drill maintenance technical services

Key words:

Iron drill maintenance technical services

Classification:

- Project Description

- Device Details

-

- Commodity name: Iron drill maintenance technical services

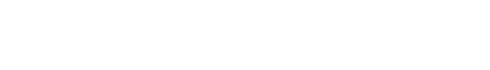

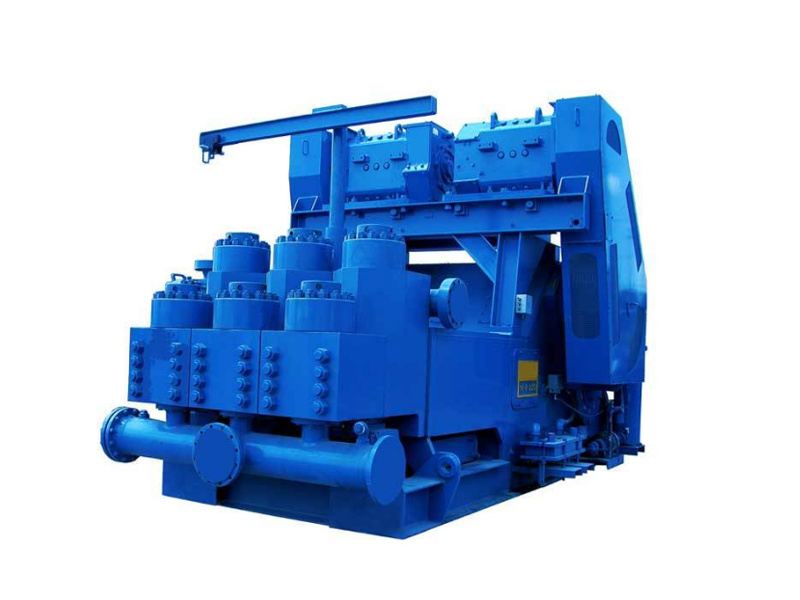

Appearance inspection and recording: Check the appearance of the iron drill worker, including the drive device, control system, hydraulic system, clamp head, and jaws, to see if there is any obvious wear, cracks, corrosion, or damage.

1. Appearance inspection and recording: Check the appearance of the iron drill, including the drive device, control system, hydraulic system, jaw head, and jaw, to see if there is any obvious wear, cracks, corrosion, or damage. Record the equipment's usage and historical failure information.

2. Disassembly and cleaning: Disassemble the main components of the iron drill, such as the hydraulic cylinder, gears, bearings, jaw head, and jaw, and thoroughly clean each component to remove oil, mud, and other deposits.

3. Wear detection and measurement:

Hydraulic system: Assess the sealing and working condition of the hydraulic system's pipes, valves, and oil cylinders.

Jaw head and jaw: Check the wear condition of the jaw head and jaw teeth, especially the clamping accuracy and wear degree of the jaw teeth, to ensure they can safely grip the drill rod.

Drive and control system: Check the wear and clearance of the drive components and bearings of the rotating and lifting mechanisms.

4. Repair and replacement: Based on the inspection results, repair or replace damaged or severely worn components, such as hydraulic cylinders, jaw heads, jaws, bearings, gears, and seals, to ensure the iron drill returns to normal function.

5. Lubrication and assembly: Add lubricants to each component to ensure smooth operation after assembly. Reassemble each component as required, ensuring precise fit to guarantee the reliability and work efficiency of the iron drill.

6. Performance testing and adjustment: Perform performance tests on the overhauled iron drill, including no-load and load tests, to ensure the hydraulic system pressure is normal, the clamping force of the jaw head meets standards, and the drive system operates smoothly, making adjustments as necessary.

7. Safety inspection and delivery: Conduct a safety performance inspection on the overhauled iron drill, confirming that all safety devices, such as emergency stop switches and overload protection, are functioning normally. After the overhaul is completed, deliver the equipment for use. -

NOV

ST-160

ST-120ST-100

ST-80CAR3200

MPT-270ARN-270

The next one:

Messages

If you are interested in our products, please leave your email, we will contact you as soon as possible, thank you!

Vanwell Oil Equipment(Tianjin)Co.,Ltd.