Turntable repair technical services

Key words:

Turntable repair technical services

Classification:

- Project Description

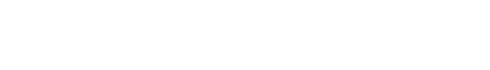

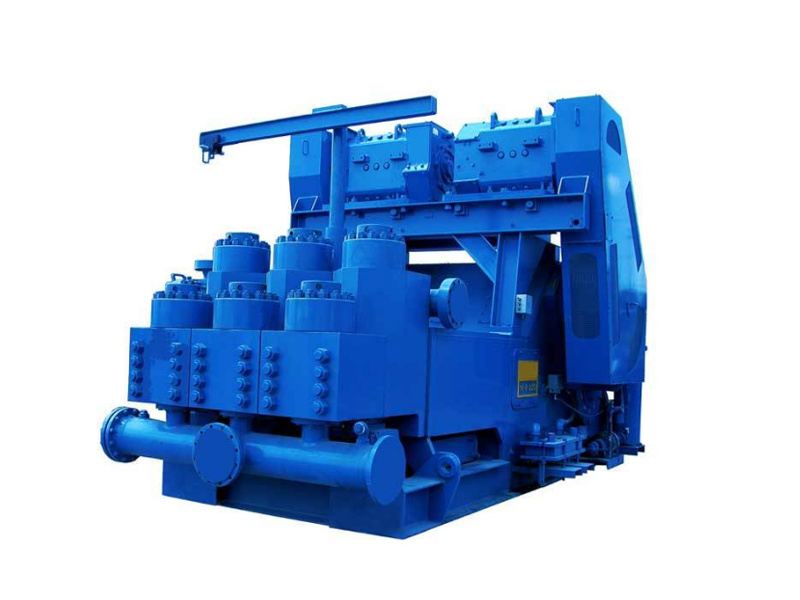

- Device Details

-

- Commodity name: Turntable repair technical services

Appearance inspection and recording: Conduct a preliminary inspection of the external structure, components, and overall condition of the turntable, checking for wear, cracks, or deformation, and record the usage and failure conditions of the equipment.

1. Appearance inspection and recording: Conduct a preliminary inspection of the external structure, components, and overall condition of the turntable, checking for wear, cracks, or deformation, and record the usage and failure conditions of the equipment.

2. Disassembly and cleaning: Disassemble the main components of the turntable, such as gears, bearings, seals, and drive devices, and thoroughly clean all disassembled parts to remove oil, dirt, and other impurities.

3. Wear detection and measurement:

Gears, bearings, and rotating components: Check the wear condition of gears and bearings, especially the tooth shape wear of gears and the rotational flexibility of bearings, and measure the wear amount and clearance of key parts.

Seals and rotating drive devices: Check for aging and damage of seals to ensure good sealing performance; conduct a detailed inspection of the connection points and lubrication condition of the rotating drive device.

4. Repair and replacement: Based on the wear detection results, repair or replace severely worn parts, such as gears, bearings, seals, etc., to ensure smooth rotation and working accuracy of the turntable.

5. Lubrication and assembly: Re-add lubricating oil or grease to all key parts of the turntable to ensure sufficient lubrication during operation and avoid friction damage. Reassemble all components according to technical specifications to ensure tight fit and assembly quality.

6. Performance testing and adjustment: Conduct no-load and load operation tests on the overhauled turntable, checking whether its operation stability, noise, vibration, etc., are within normal ranges. If problems are found, make necessary adjustments to ensure the rotation accuracy and load capacity of the turntable meet requirements.

7. Safety inspection and delivery: Inspect all safety devices of the turntable to ensure the normal operation of safety locking devices and protective devices. After confirming that all functions and performance meet standards, deliver the equipment for use. -

NOV 宝鸡石油机械 RST-375 RST-605 ZP375 RST-495 RST-605-F ZP375Z RST-495-F RST-605-H ZP495 RST-495-H RST-755

The next one:

Messages

If you are interested in our products, please leave your email, we will contact you as soon as possible, thank you!

Vanwell Oil Equipment(Tianjin)Co.,Ltd.