Technical services for electrical control systems of oil drilling rigs

Key words:

Technical services for electrical control systems of oil drilling rigs

Classification:

- Project Description

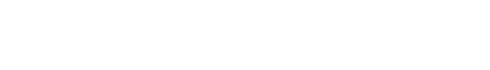

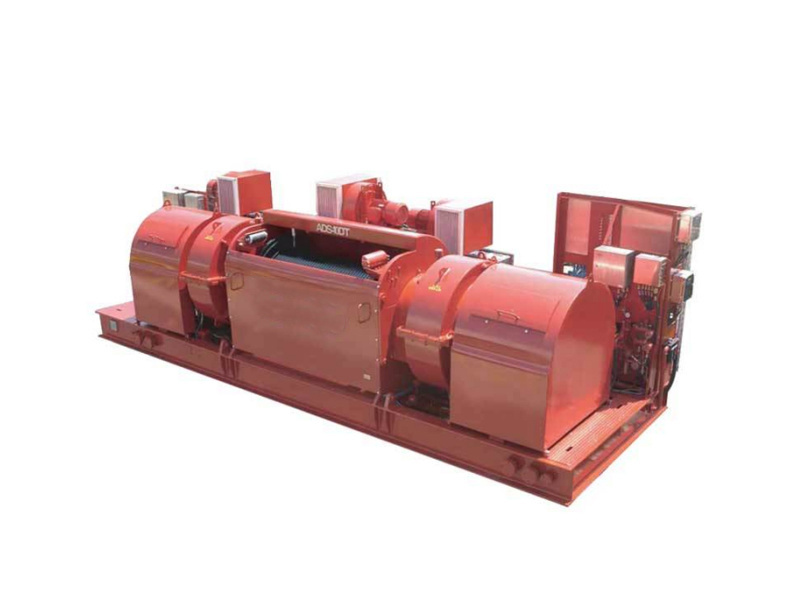

- Device Details

-

- Commodity name: Technical services for electrical control systems of oil drilling rigs

According to the layout of the drilling rig and the design requirements of the electrical control system, install equipment such as control cabinets, operation consoles, sensors, and actuators. Ensure that the equipment is installed securely, in the correct position, and is convenient for operation and maintenance.

System Installation and Debugging

1. Equipment Installation

Install equipment such as control cabinets, operation consoles, sensors, and actuators according to the layout of the drilling rig and the design requirements of the electrical control system. Ensure that the equipment is installed securely and accurately positioned for ease of operation and maintenance.

Carry out cable laying, ensuring that cable connections are correct, neat, and comply with electrical safety regulations.

2. System Debugging

Conduct pre-power-on checks of the electrical control system, including checks on wiring connections, grounding, insulation, etc., to ensure the system is safe and reliable.

Set and debug system parameters, such as motor speed control parameters, protection parameters, control logic, etc. Through debugging, optimize system performance to meet the operational requirements of the drilling rig.

Daily Maintenance and Inspection

1. Regular Maintenance

Develop a maintenance plan and regularly maintain the electrical control system. This includes cleaning equipment, checking cable connections, tightening screws, and replacing worn parts.

Conduct regular inspections and maintenance of key equipment such as motors, transformers, and inverters, including measuring motor insulation resistance, checking transformer oil levels, and cleaning inverter cooling fans.

2. Inspection Services

Arrange for professional technicians to conduct regular inspections of the drilling rig's electrical control system to promptly identify and address potential issues. Inspection content includes equipment operating status, instrument indications, alarm information, etc.

Record and analyze issues found during inspections, propose improvement suggestions, and ensure stable system operation.

Fault Diagnosis and Repair

1. Fault Diagnosis

When a fault occurs in the electrical control system, technicians respond quickly, determining the cause of the fault through on-site inspections and instrument testing.

Utilize professional fault diagnosis software and tools to conduct a comprehensive analysis of the system, improving the accuracy and efficiency of fault diagnosis.

2. Repair Services

Based on the fault diagnosis results, take appropriate repair measures. This includes replacing damaged components, repairing circuit faults, and adjusting parameters.

For major faults, develop a detailed repair plan to ensure that repair work is conducted safely and efficiently. After repairs are completed, conduct system testing and acceptance to ensure the system returns to normal operation.

Technical Upgrades and Modifications

1. Technical Upgrades

With the continuous development of technology, provide technical upgrade services for the drilling rig's electrical control system, such as updating control system software, upgrading hardware, and improving system automation levels.

Through technical upgrades, enhance the performance and reliability of the system to meet the ever-changing requirements of drilling processes.

2. Modification Services

Modify the existing electrical control system according to the special needs of customers. For example, add new functional modules, optimize control logic, and improve system compatibility.

During the modification process, fully consider the safety and stability of the system to ensure that the modified system can operate normally.

Training and Technical Support

1. Training Services

Provide training services for drilling rig operators and maintenance personnel on the electrical control system. Training content includes system operation methods, daily maintenance points, fault diagnosis and handling, etc. Through training, improve the skill level of operators, reduce human errors, and extend the system's lifespan.

2. Technical Support

Provide 24-hour technical support services to answer any questions customers encounter during use.

Establish technical support records to document and analyze customer issues, continuously improving service quality.

Previous:

The next one:

Messages

If you are interested in our products, please leave your email, we will contact you as soon as possible, thank you!

Vanwell Oil Equipment(Tianjin)Co.,Ltd.