Crane and vehicle maintenance technical services

Key words:

Crane and vehicle maintenance technical services

Classification:

- Project Description

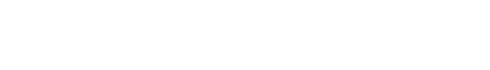

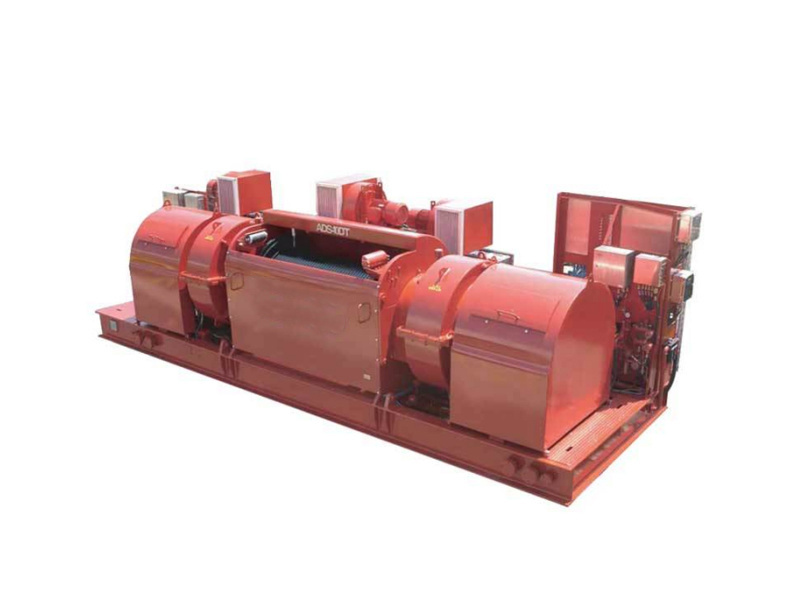

- Device Details

-

- Commodity name: Crane and vehicle maintenance technical services

Appearance inspection and recording: Conduct a comprehensive inspection of the appearance condition of the overhead crane and the trolley, including the status of various connecting components, the condition of the wire ropes, as well as the wear of pulleys and bearings, and carefully document the operating conditions and fault information of the equipment.

1. Appearance Inspection and Recording: Conduct a comprehensive inspection of the appearance of the overhead crane and the trolley, including the condition of various connection components, the state of the wire rope, and the wear of pulleys and bearings, and record the operating conditions and fault information of the equipment in detail.

2. Disassembly and Cleaning: Disassemble the main components of the overhead crane and trolley, such as pulleys, pins, brackets, and connectors, and thoroughly clean all disassembled parts to remove oil, dirt, and other attachments.

3. Wear Detection and Measurement:

Pulleys and Bearings: Check the wear condition of the grooves of the pulleys and the degree of wear of the bearings to ensure smooth operation of the pulleys and free rotation of the bearings.

Wire Rope and Connectors: Inspect the wear, broken wires, and safety factor of the wire rope, and check the wear and fastening condition of the connectors.

Pins and Brackets: Check the wear and corrosion of the pins and assess whether the brackets have deformation or cracks.

4. Repair and Replacement: Based on the inspection results, repair or replace worn or damaged pulleys, bearings, wire ropes, pins, and connectors to ensure that key components restore safe and stable operating performance.

5. Lubrication and Assembly: Add an appropriate amount of lubricating oil or grease to various parts of the overhead crane and trolley to ensure that the components are adequately lubricated during operation. Reassemble the components according to technical requirements to ensure tight fitting between parts, eliminating gaps and looseness.

6. Performance Testing and Adjustment: Conduct load and no-load tests on the overhauled overhead crane and trolley to check their stability and safety during operation, ensuring that key components such as pulleys and bearings operate well, and make adjustments if necessary.

7. Safety Inspection and Delivery: Conduct a comprehensive safety performance inspection, including checking and testing all safety devices, locking components, and protective devices to ensure that the equipment meets safety standards. After confirming that everything is correct, deliver the equipment for use. -

NOV 宝鸡石油机械 CB-750 TC450 YC450 CB-1000 TC585 YC585 CB-1500 TC675 YC675 TB-750 TC675H YC900 TB-1000 TC900 TB-1500 YC450

Previous:

The next one:

Messages

If you are interested in our products, please leave your email, we will contact you as soon as possible, thank you!

Vanwell Oil Equipment(Tianjin)Co.,Ltd.