Mud pump maintenance technical services

Key words:

Mud pump maintenance technical services

Classification:

- Project Description

- Device Details

-

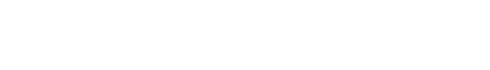

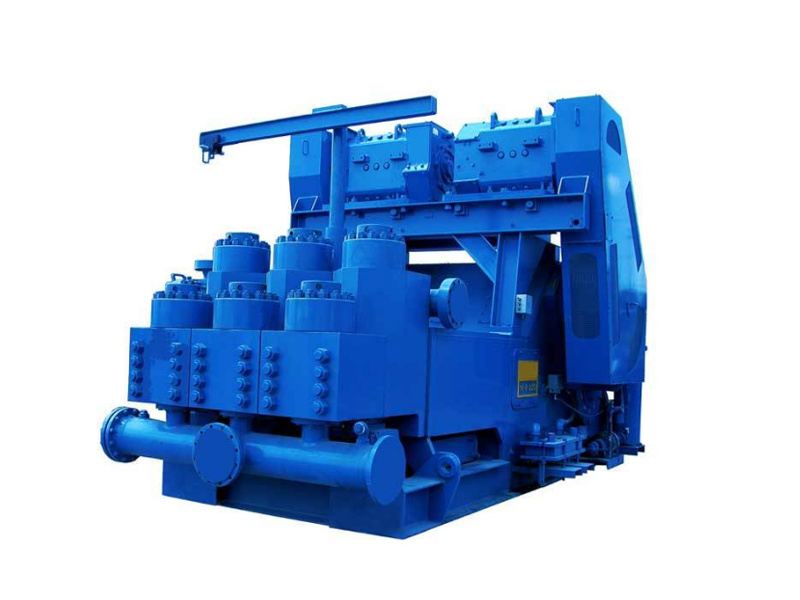

- Commodity name: Mud pump maintenance technical services

Appearance inspection and recording: Conduct a comprehensive inspection of the mud pump's appearance, pipelines, seals, and connections for any damage, wear, or corrosion, and record the equipment's operating history and failure conditions.

1. Appearance inspection and recording: Conduct a comprehensive inspection of the appearance of the mud pump, pipelines, seals, and connections for any damage, wear, or corrosion, and record the equipment's operating history and failure conditions.

2. Disassembly and cleaning: Disassemble the main components of the mud pump, such as the pump body, piston, cylinder sleeve, valve, and crankcase, and clean all parts to ensure there is no oil sludge or sediment, facilitating subsequent inspection and maintenance.

3. Wear detection and measurement:

Cylinder sleeve, piston, valve group: Check the wear condition of the cylinder sleeve and piston, and test the sealing performance of the valve and valve seat.

Crankshaft, bearings, connecting rods: Detect the wear and clearance of components such as the crankshaft, bearings, and connecting rods to determine if repair or replacement is needed.

4. Repair and replacement: Based on the inspection results, repair or replace worn parts such as cylinder sleeves, pistons, seals, bearings, and valves to ensure that all components restore their original performance.

5. Lubrication and assembly: Add an appropriate amount of lubricating oil or grease to each component to minimize wear under normal working conditions. Reassemble all components according to technical specifications to ensure assembly accuracy.

6. Performance testing and adjustment: Conduct no-load and load tests to check the operating status of the mud pump, including pressure, flow, vibration, noise, etc., to ensure it restores normal working capacity. If performance does not meet requirements, make necessary adjustments.

7. Safety inspection and delivery: Finally, conduct a comprehensive safety inspection, including checking the sealing and reliability of fasteners, to ensure the safety and effectiveness of the equipment for on-site use. Confirm everything is correct before delivery. -

NOV 宝鸡石油机械 F-1000 F-1600 F-1300 F-1600HL F-1600 F-1600L FG-1600 F-2200 National 14-P-220 F-2200HL National 12-P-160 QDP-3000 National 10-P-130

Previous:

The next one:

Messages

If you are interested in our products, please leave your email, we will contact you as soon as possible, thank you!

Vanwell Oil Equipment(Tianjin)Co.,Ltd.